Introduction

Thermal printers are an essential component in various industries, including retail, logistics, healthcare, and banking. Unlike traditional inkjet or laser printers, thermal printers use heat to produce images on specially treated paper or labels. While these printers offer numerous advantages, such as low maintenance, speed, and cost-efficiency, they are also susceptible to wear and tear over time. If not properly maintained, thermal printers can experience a decline in print quality, frequent breakdowns, and even permanent damage, leading to increased operational costs.

For businesses that rely on thermal printing technology, it is crucial to implement measures that extend the life of these devices. Proper care and regular maintenance can ensure that thermal printers continue to function optimally for years. At DumpsQueen Official, we understand the importance of printer longevity, and this article will provide an in-depth guide on how to extend the life of a thermal printer.

The Importance of Maintaining a Thermal Printer

Maintaining a thermal printer is not just about ensuring smooth operation—it also plays a significant role in business efficiency and cost savings. When a thermal printer malfunctions, it can cause delays, leading to customer dissatisfaction and potential financial losses. Additionally, purchasing new printers frequently due to neglect can become a costly endeavor.

Regular maintenance helps prevent premature wear and tear, reduces the frequency of repairs, and enhances print quality. A well-maintained thermal printer ensures that receipts, barcodes, and labels are printed clearly and accurately, which is critical for industries that rely on precise information.

Choosing the Right Thermal Paper and Ribbons

One of the most important aspects of maintaining a thermal printer is selecting the appropriate thermal paper and ribbons. Many businesses make the mistake of using low-quality materials, which can lead to poor print quality and increased wear on the printhead.

Using high-quality thermal paper reduces the buildup of residue and dust, which can clog the printhead and lead to malfunctions. Additionally, for thermal transfer printers, it is essential to use compatible ribbons that do not leave excess wax or resin on the printhead. Choosing the correct materials ensures that the printer operates smoothly and prevents unnecessary damage.

Cleaning and Maintaining the Printhead

The printhead is one of the most critical components of a thermal printer. It is responsible for applying heat to the paper or ribbon, creating the printed image. Over time, the printhead can accumulate dust, adhesive residue, and other debris, leading to poor print quality and eventual failure.

To maintain the printhead, it is essential to clean it regularly using a specialized cleaning pen or isopropyl alcohol wipes. Gently wiping the printhead removes any residue that may have built up over time. Additionally, avoiding excessive pressure when cleaning the printhead helps prevent damage to its delicate components.

Preventing Overheating in Thermal Printers

Overheating is a common issue that can significantly shorten the lifespan of a thermal printer. Since these printers rely on heat to produce images, excessive heat exposure can lead to premature wear and damage to the printhead. Businesses that frequently use thermal printers for high-volume printing must take extra precautions to prevent overheating.

One way to mitigate overheating is by adjusting the print density settings. Lowering the print density reduces the amount of heat required to produce an image, thereby extending the life of the printhead. Additionally, allowing the printer to cool down between high-volume print jobs can prevent excessive wear. Proper ventilation around the printer is also crucial to dissipate heat effectively.

Proper Handling and Storage of Thermal Printers

Thermal printers should be handled with care to prevent unnecessary wear and mechanical stress. Many users unknowingly cause damage to their printers by mishandling components or storing them improperly.

When loading paper or ribbons, it is important to follow the manufacturer’s instructions to avoid misalignment or jamming. Additionally, the printer lid should be opened and closed gently to prevent damage to the internal mechanisms. Storing the printer in a clean, dust-free environment further helps prevent the accumulation of debris that can affect performance.

Environmental factors also play a crucial role in the longevity of a thermal printer. Exposure to extreme temperatures, humidity, or direct sunlight can damage internal components and degrade thermal paper quality. Keeping the printer in a stable environment ensures consistent performance and extends its lifespan.

Updating Firmware and Using Manufacturer-Recommended Parts

Just like other electronic devices, thermal printers receive firmware updates from manufacturers to enhance performance and fix potential issues. Regularly updating the firmware ensures that the printer operates with the latest optimizations and security patches.

Using manufacturer-recommended parts and accessories is also essential. Non-genuine replacement parts may not be designed to the same quality standards, leading to compatibility issues and increased wear. Investing in genuine replacement components ensures that the printer maintains its original performance and longevity.

Common Problems and Their Solutions

Even with proper maintenance, thermal printers can encounter issues. Below are some common problems and their solutions:

-

Faded Prints: If the prints appear faded, it may be due to low print density settings or worn-out thermal paper. Adjusting the print density settings and replacing the paper with a high-quality alternative can resolve this issue.

-

Paper Jams: Paper jams can occur when the paper is not loaded correctly. Ensuring that the paper is properly aligned and removing any debris from the feed path can help prevent jams.

-

Streaks on Prints: Streaks on printed documents often indicate a dirty or damaged printhead. Cleaning the printhead with a specialized cleaning pen can restore print quality.

-

Connectivity Issues: If the printer is not connecting to the computer or network, checking the cables, updating drivers, and ensuring the correct settings are configured can help resolve connectivity issues.

Conclusion

Thermal printers are an invaluable tool in various industries, and extending their lifespan is essential for cost efficiency and smooth business operations. By following proper maintenance practices, using high-quality materials, preventing overheating, and handling the printer with care, businesses can ensure that their thermal printers operate at peak performance for years.

At DumpsQueen Official, we emphasize the importance of printer maintenance and efficiency. Investing in regular cleaning, firmware updates, and proper handling not only extends the life of a thermal printer but also enhances productivity and minimizes downtime. Implementing these best practices will lead to better print quality, reduced repair costs, and long-term savings.

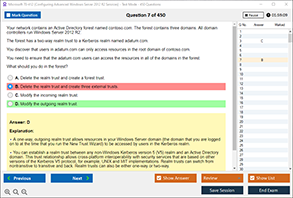

Free Sample Questions

1. What is one of the main causes of printhead failure in thermal printers?

a) Using high-quality thermal paper

b) Accumulation of dust and residue

c) Printing at a low speed

d) Regular maintenance

Answer: b) Accumulation of dust and residue

2. How can overheating of a thermal printer be prevented?

a) By increasing print density settings

b) By allowing cool-down periods between high-volume prints

c) By storing the printer in direct sunlight

d) By using low-quality ribbons

Answer: b) By allowing cool-down periods between high-volume prints

3. Why is it important to use manufacturer-recommended parts for a thermal printer?

a) They are more expensive

b) They improve print speed

c) They ensure compatibility and longevity

d) They require frequent replacement

Answer: c) They ensure compatibility and longevity